The Versatility of Applications of Spirall Storage Tanks Across Multiple Industries

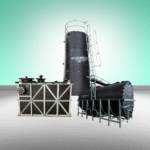

In Today’s Industrial Landscape, Efficient Storage Solutions are Crucial for Maintaining the Flow of Operations. Among the Many Options Available, Spirall Storage Tanks Stand Out for Their Unique Design and Impressive Versatility. These Tanks are Not Only Durable but Also Space-Efficient and Adaptable to a Wide Range of Materials. in This Blog, We Will Explore the Benefits of Spirall Storage Tanks and Identify the Types of Industries that Can Best Utilize These Innovative Storage Solutions.

The Advantages of Spirall Storage Tanks

- Durability:

Spirall Storage Tanks are Constructed with a Continuous Spirall Winding Technique, Which Significantly Enhances Their Structural Integrity. This Method of Construction Minimizes the Risk of Weak Points, Making These Tanks Exceptionally Durable. They are Capable of Withstanding High Pressure and Temperature Variations, Which Makes Them Ideal for Storing Volatile or Corrosive Substances. Their Robust Nature Ensures a Longer Lifespan Compared to Traditional Storage Tanks, Reducing the Need for Frequent Replacements and Maintenance. - Space Efficiency:

One of the Key Benefits of Spirall Storage Tanks is Their Space-Saving Design. the Spirall Construction Allows for the Creation of Tanks with a Higher Storage Capacity in a Relatively Small Footprint. This Is Particularly Beneficial in Industries Where Space is at a Premium. The compact Design Doesn’t Compromise on Storage Volume, Making It an Ideal Choice for Facilities Looking to Maximize Their Storage Capacity Without Expanding Their Physical Space. - Adaptability to Various Materials:

Spirall Storage Tanks are Highly Adaptable and Can Be Tailored to Store a Wide Range of Materials, Including Liquids, Chemicals, Food Products, and Gases. the Tanks Can Be Lined or Coated with Specific Materials to Resist Corrosion or Contamination, Ensuring the Safe Storage of Aggressive Chemicals or Sensitive Substances. Whether It’s Food-Grade Liquids or Hazardous Chemicals, Spirall Storage Tanks Can Be Customized to Meet the Specific Requirements of the Stored Material.

Industries that Benefit from Spirall Storage Tanks

- Given Their Versatility, Spirall Storage Tanks Find Applications Across a Wide Array of Industries. Here are Some Examples:

- Chemical Industry:

the Chemical Industry Often Requires Storage Solutions that Can Handle Highly Corrosive and Reactive Substances. Spirall Storage Tanks, with Their Customizable Linings and Robust Construction, are Ideal for Storing Acids, Bases, Solvents, and Other Chemicals. Their Durability Ensures that They Can Safely Contain These Substances Without the Risk of Leaks or Contamination. - Food and Beverage Industry:

in the Food and Beverage Sector, the Storage of Liquids Like Oils, Juices, and Syrups Demands Tanks That Maintain the Purity and Quality of the Products. Spirall Storage Tanks, Made with Food-Grade Materials and Coatings, Offer a Hygienic Solution for Storing These Liquids. Their Space Efficiency Is Also a Major Advantage in Facilities Where Space Is Limited. - Pharmaceutical Industry:

Pharmaceutical Manufacturers Require Storage Solutions that Ensure the Integrity and Safety of Their Products. Spirall Storage Tanks Can Be Designed to Meet Stringent Cleanliness Standards and are Often Used to Store Bulk Liquids, Such as Active Pharmaceutical Ingredients (Apis) or Solvents. the Adaptability of These Tanks Allows Them to Be Configured to Meet Specific Regulatory Requirements, Making Them a Reliable Choice for This Highly Regulated Industry. - Oil and Gas Industry:

in the Oil and Gas Industry, Storage Tanks Must Withstand Harsh Environmental Conditions and Handle the Storage of Volatile Substances. Spirall Storage Tanks are Designed to Endure High Pressure and Temperature Extremes, Making Them Suitable for Storing Crude Oil, Natural Gas, and Refined Products. Their Durability and Adaptability Ensure Safe and Efficient Storage in Both Upstream and Downstream Operations. - Water Treatment Industry:

Water Treatment Facilities Often Require Large Storage Tanks for Holding Treated Water or Chemicals Used in the Treatment Process. Spirall Storage Tanks, with Their Corrosion-Resistant Properties and Large Capacity, are Well-Suited for These Applications. They Offer a Long-Lasting Solution for Storing Both Potable Water and Industrial Water Treatment Chemicals.

Conclusion

Spirall Storage Tanks Offer a Versatile and Reliable Storage Solution for a Variety of Industries. Their Durability, Space Efficiency, and Adaptability to Different Materials Make Them an Attractive Option for Businesses Looking to Optimize Their Storage Capabilities. Whether You’re in the Chemical, Food and Beverage, Pharmaceutical, Oil, Gas, or Water Treatment Industry, Spirall Storage Tanks Can Provide the Robust and Efficient Storage Solution You Need to Keep Your Operations Running Smoothly.

A. V Plastics is a leading manufacturer and supplier of Spiral Storage Tanks, specializing in high-quality plastic equipment for diverse industrial applications. Our expertise spans Spiral Products, Composite Products, and Lining Equipment, ensuring durable, corrosion-resistant solutions tailored to industry needs. With a commitment to innovation and quality, we provide reliable storage and processing solutions for various sectors.